Alumina Apex (Sedimentation)

A cyclone or hydrocyclone, shaped like a container, is utilized for segregating fine from coarse particles. The conical bottom and outlet are referred to as the cyclone bottom or apex. Ceramic apexes, resembling funnels and crafted from alumina, are essential due to their exposure to abrasive materials, necessitating high wear resistance and cold compressive strength.

- Composition: Made of alumina ranging from 92 to 96% purity.

- Density: Ranges between 3.6 to 3.8 grams per cubic centimeter.

- Wear Resistance: Engineered to be anti-wear for longevity in harsh environments.

- Application: Serves as a material outlet nozzle in various industries.

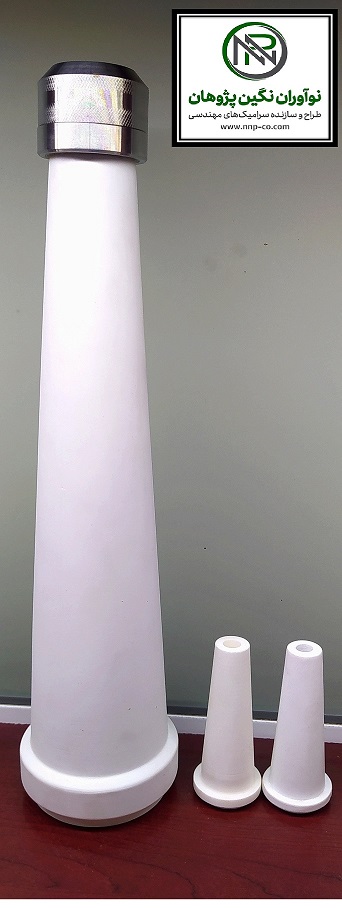

Conical Ceramic Body of the Cleaner Machine

In the paper production process, the cleaner machine plays a crucial role in purifying the fibrous fluid by removing heavy contaminants such as sand, glass fragments, and iron particles, which is essential for producing the initial paper pulp. The process begins at the cleaner’s upper spiral entry, where the paper pulp is introduced. It then starts to rotate, moving circularly at the correct pressure and velocity. This motion generates centrifugal force within the cylinder, causing the heavier particles to move outward toward the cylinder’s walls. These impurities, including sand and other heavy particles, are then guided down to the cleaner’s lower section, typically shaped like a pot, which serves as the collection point for the discarded paste.

For the inaugural time in the region, Noavaran Negin Pajouhan Company has innovatively crafted the conical segment at the terminal end of the cleaner using a durable ceramic material, shaped through the cold isostatic pressing (CIP) technique.

Specifications:

- Material Composition: Alumina with a 92% to 96% purity range.

- Material Density: Between 3.6 to 3.8 grams per cubic centimeter.

- Durability: Engineered for high resistance to wear.

Aluminum Rods and Pipes

- Material Composition: Crafted from alumina with a purity ranging from 92% to 99%.

- Density: Between 3.6 to 3.8 grams per cubic centimeter.

- Durability: Designed to be resistant to wear, ensuring a longer lifespan.

- Heat Resistance: Capable of withstanding high temperatures without degradation.

Aluminum Blocks and Plates

- Material Quality: Composed of high-purity alumina, ranging from 92% to 99%.

- Density: Between 3.6 to 3.8 grams per cubic centimeter.

- Durability: Engineered to resist wear, they maintain their integrity even under rigorous use.

- Impact Resistance: Built to withstand impacts, ensuring resilience in challenging environments.

Aluminum Rims and Washers

- Material Composition: Constructed from alumina with a purity ranging from 92% to 99%.

- Density: Between 3.6 to 3.8 grams per cubic centimeter density.

- Wear Resistance: Designed with anti-wear properties to enhance durability.

- Sealing Function: Serve as mechanical seals, providing a secure fit in various applications.

Aluminum Industrial Components

- Extruded Mold

- Material Spraying Nozzle

- Ceramic Thread Guide