Our laboratory offers comprehensive metallurgical tests that adhere to national and international standards. These tests include:

-

Chemical analysis to determine the elemental composition of materials.

-

Structural analysis of ferrous and non-ferrous metals to assess their microstructure.

-

Ceramography for a detailed examination of ceramic materials.

-

Welding process examination, including evaluating oil and gas transmission pipeslines and Procedure Qualification Records (PQR).

-

Forming process examination, covering hot rolling, cold rolling, and casting techniques.

-

Polymers property examination to evaluate strength, flexibility, and durability.

-

Surface and coating engineering process examination involve measuring coating thickness, assessing quality, and testing coating adhesion.

Optical Microscope

The Olympus BH60 optical microscope is a sophisticated instrument that offers a range of features for detailed material analysis:

- Magnification up to 2000 times.

- Utilizes both chemical and thermal etching techniques to prepare samples for examination.

- Capable of using transmitted, reflective, and polarized light (both Dark & Bright Fields).

- High-resolution photography of both polished and etched surfaces.

- Facilitates the examination of the microstructure of ferrous and non-ferrous metals.

- Suitable for analyzing the structure of coatings and surface treatments.

- Enables the study of welding structures and solidification patterns.

- Provides the ability to check for welding defects using the macro etching method, which reveals defects not visible to the naked eye.

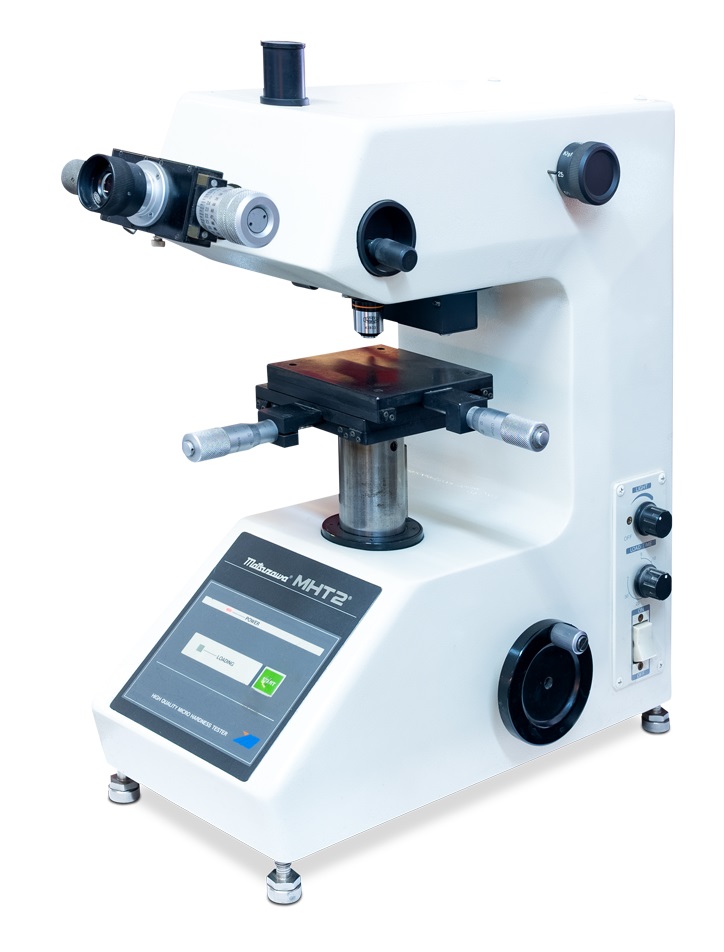

Micro Hardness Testing

The Matsuzawa Microhardness Tester is a tool for material analysis, offering:

- Vickers microhardness measurement

- Analysis of hardness profiles and accurate determination of hardness penetration depth.

- Loading range from 5 to 1000 grams

- Precise hardness measurement of different phases, coatings, and layers.

- The ability to measure the hardness of materials ranges from very soft to very hard.

Universal Hardness Tester KOOPA-UV1

The KOOPA universal digital hardness tester- UV1 is a comprehensive tool for material hardness testing, offering:

- Hardness testing of metals using the Rockwell (A, B, C), Brinell, and Vickers methods, with a scale range from 1 kg to 187.5 kg.

- Compliance with ASTM standards, specifically ASTM E18, ASTM E10, and ASTM E92, ensuring tests are performed to industry specifications.

- The capability to convert measured values between different hardness scales (Rockwell, Brinell, and Vickers).

Fritsch A22 Laser Particle Sizer Analyzer

The Fritsch A22 laser particle analyzer is designed for detailed particle characterization, offering the following capabilities:

- Measurement of particle size distribution and specific surface area of chemical and ceramic powders.

- A broad measurement range from 300 nm to 1000 microns.

- The ability to measure in a wet system, suitable for analyzing suspended particles.

- Plotting the particle size distribution curve, providing a visual representation of particle size variability.

- Drawing the curve of relative abundance, illustrating the frequency of different particle sizes within a sample.

- Measuring statistical parameters such as mean, median, and standard deviation offers insights into the central tendency and dispersion of particle sizes.

- Determination of D50, D10, and D90 parameters

- Utilizing an ultrasonic system to ensure better uniformity in sample preparation.

TIME TH160 Portable Hardness Tester

The Leebs portable metal hardness tester (Time TH160) is designed for practical in-field hardness testing of metals, with the following features:

- Capable of measuring the hardness of metals weighing more than 5 kg directly in-site.

- Offers the flexibility to convert measured values into other recognized hardness scales, including Rockwell, Brinell, and Vickers.

Shore Hardness Tester TH210 and TH200

The Time TH210 and TH200 models are designed for the hardness testing of elastic and plastic polymers, featuring:

- Hardness measurement capabilities on the SHORE A and D scales, which are suitable for a wide range of polymer materials.

- Compliance with multiple standards, including ISO7619, ASTM D2240, DIN 53505, and JIS K7215